Parallel Twin Screw Barrel: A Comprehensive Guide to Modern Processing Technology

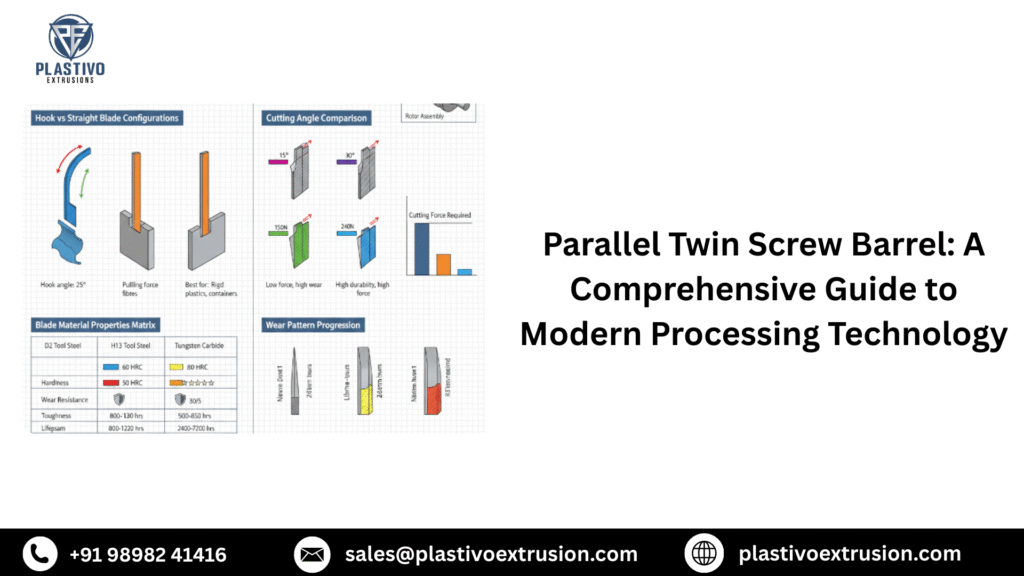

Ahmedabad, Gujarat GST No.-24AAVHA8297E1ZU +91 98982 41416 Linkedin-in Instagram Whatsapp Home About us ☰ Our Product Auxiliary Equipment Extruders Pipe Making Machine Plastic Recycling Machine Screw Barrel Blogs Contact us Home About us ☰ Our Product Auxiliary Equipment Extruders Pipe Making Machine Plastic Recycling Machine Screw Barrel Blogs Contact us Request Appointment Parallel Twin Screw Barrel: A Comprehensive Guide to Modern Processing Technology Introduction The performance of any plastic shredding system ultimately depends on one critical component: the cutting blade. While motors provide power and frames provide structure, the blade geometry determines how efficiently plastic materials are reduced to the desired size. Understanding the intricate relationship between blade design, cutting mechanics, and material properties separates mediocre shredding operations from highly efficient, cost-effective systems. This technical examination explores the engineering principles behind blade design, the physics of cutting different plastic materials, and the practical considerations that influence blade selection and maintenance strategies in industrial recycling operations. Hook Blade vs. Straight Blade Configurations The fundamental decision in blade design starts with choosing between hook and straight blade configurations. Each geometry creates distinctly different cutting actions that suit specific applications and material types. Hook blades feature a curved or hooked profile that creates a scissors-like cutting action as the blade passes the material. This geometry excels at grabbing and pulling material into the cutting zone, making it particularly effective for film materials, fiber-reinforced plastics, and materials that tend to slip away from straight cutting edges. The hook angle, typically ranging from 15 to 35 degrees from vertical, determines how aggressively the blade captures material. The curved profile generates both a cutting force and a pulling force simultaneously. As the blade rotates, the hook engages the material first at the tip, then progressively cuts along the entire edge length. This action distributes cutting forces over time rather than applying them instantaneously, reducing peak power demands and creating smoother operation with less vibration. Straight blades present a flat cutting edge perpendicular to the direction of rotation. This configuration delivers pure shearing action without the pulling component found in hook blades. Straight blade geometry proves superior for rigid plastics like PET bottles, HDPE containers, and thick-walled parts where the material maintains its position during cutting rather than deflecting away. The absence of a hook allows straight blades to maintain more consistent edge geometry during sharpening and reconditioning. Manufacturing tolerances are easier to achieve, and replacement costs typically run 15 to 25 percent lower than equivalent hook blade designs. However, throughput may decrease with certain flexible materials that require the grabbing action of hooked profiles. Cutting Angle Optimization The cutting angle—measured between the blade face and the material being cut—represents one of the most critical geometric parameters affecting shredding performance. This angle directly influences cutting force requirements, edge durability, and the quality of the resulting cut. A shallow cutting angle of 15 degrees creates an extremely sharp blade that requires minimal force to penetrate material. This geometry works exceptionally well for soft plastics, films, and materials where clean cuts without significant deformation are desired. The trade-off comes in reduced edge strength; shallow angles wear more quickly and are prone to chipping when encountering hard contaminants or reinforced materials. The forces involved follow predictable patterns. Cutting force decreases proportionally as the angle becomes more acute, following the relationship F = k × t / tan(α), where F represents cutting force, k is a material constant, t is material thickness, and α is the cutting angle. A 15-degree angle might require 40 percent less force than a 45-degree configuration for the same material. Medium cutting angles around 30 degrees represent the most common compromise in industrial shredding applications. This geometry balances reasonable cutting forces with adequate edge strength for extended operational periods. Most general-purpose shredders processing mixed plastic waste employ 30-degree blade angles as a starting point, then adjust based on specific material characteristics and performance requirements. Steep cutting angles of 45 degrees prioritize edge durability over cutting efficiency. The robust edge geometry withstands impact from hard contaminants—metal fasteners, stones, wood fragments—that frequently appear in post-consumer plastic streams. While cutting forces increase substantially, the extended blade life and reduced downtime from edge damage often justify the additional power consumption. Material properties significantly influence optimal cutting angle selection. Ductile materials like LDPE and PP deform rather than fracture, requiring sharper angles to achieve clean cuts without excessive stretching. Brittle materials such as PS and rigid PVC fracture readily, allowing steeper angles without compromising cut quality. Fiber-reinforced plastics present the greatest challenge, demanding careful angle selection to cut both the matrix material and reinforcing fibers without excessive delamination. Blade Material Selection The metallurgical composition of shredder blades determines their operational lifespan, maintenance requirements, and total cost of ownership. Three primary material families dominate industrial applications, each offering distinct advantages for specific operating conditions. D2 tool steel represents the most common blade material in plastic shredding applications. This air-hardening steel contains approximately 12 percent chromium and 1.5 percent carbon, providing excellent wear resistance when properly heat-treated to hardness levels between 58 and 62 HRC. The high chromium content offers moderate corrosion resistance, important when processing washed materials or operating in humid environments. D2’s wear resistance comes from numerous hard chromium carbides distributed throughout the martensitic matrix. These carbides, significantly harder than the surrounding steel, resist abrasive wear from fillers, reinforcing fibers, and contaminants. A properly heat-treated D2 blade processing general mixed plastics typically achieves 800 to 1,200 operational hours before requiring sharpening. The material costs roughly 40 to 60 percent less than premium alternatives while delivering adequate performance for many applications. Heat treatment quality critically affects performance; improper processing can leave the blade too soft for wear resistance or too hard and brittle, prone to chipping. Reputable blade manufacturers employ precise heat treatment protocols with documented hardness verification. H13 tool steel offers superior toughness compared to D2, making it the preferred choice for heavy-duty applications involving thick-walled parts, hard contaminants, or high-impact cutting conditions. This hot-work steel contains approximately 5 percent chromium, 1.5

Parallel Twin Screw Barrel: A Comprehensive Guide to Modern Processing Technology Read More »