HDPE Pipe Making Machine and PVC Pipe Making Machine

Practical Pipe Manufacturing Solutions for Indian Factories

Pipe manufacturing in India is not just about output numbers. It is about running the machine day after day, handling power fluctuations, dealing with raw material variation, and still producing pipes that pass inspection without complaints. This is where a well-designed PVC Pipe Making Machine and HDPE Pipe Making Machine really make a difference.

Plastivo Extrusions designs machines keeping Indian working conditions in mind. Whether you are producing PVC conduit pipes for electrical wiring or heavy-duty HDPE pipes for water, gas, and agriculture, these machines focus on stability, consistent quality, and long working life rather than fancy claims.

PVC Conduit Pipe Making Machine – Technical Specifications

| Specification | Details |

|---|---|

| Capacity | 250 kg/hr |

| Automation Grade | Automatic |

| Power Consumption | 75 KW |

| Brand | Plastivo Extrusions |

| Material | Stainless Steel and High-Quality Alloys |

| Heating Zones | 6 Zones |

| Cooling System | Vacuum Cooling Tanks and Water Sprays |

| Control System | PLC-Based Automation |

| Country of Origin | Made in India |

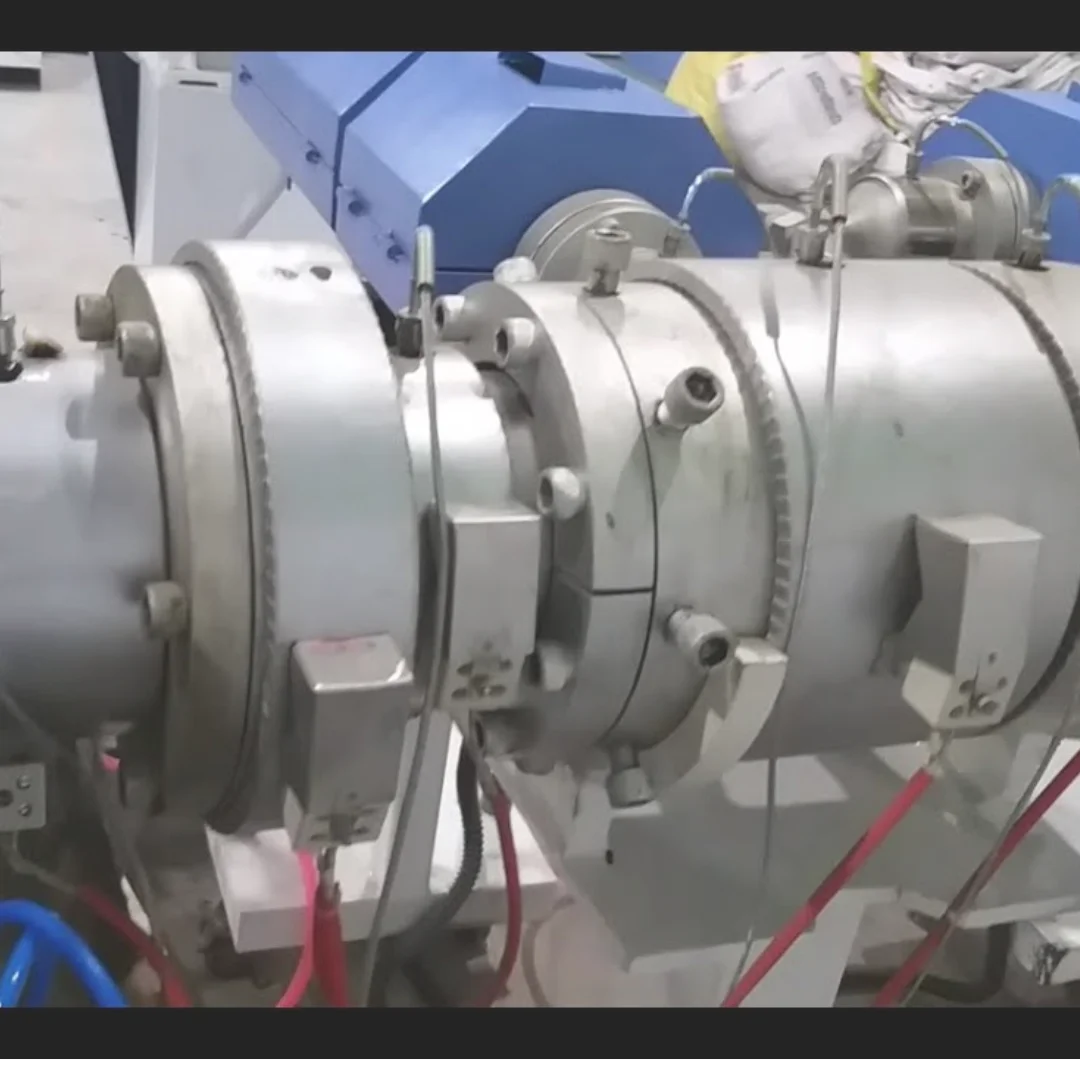

PVC Pipe Making Machine for Conduit Pipe Production

The PVC Pipe Making Machine by Plastivo Extrusions is commonly used in making electrical and plumbing conduit pipes. When it comes to buildings, whether residential, office, factory, or other establishments such as shopping centers and infrastructure, conduit pipes are always in demand. Since conduit pipes have to be of equal size, smooth, and strong, temperature and cooling regulation in the extrusion setup assumes importance.

This PVC conduit pipeline is fully automatic and built for continuous operation. It is suitable for manufacturers who want reliable production without frequent breakdowns or complicated operations.

How the PVC Pipe Making Machine Performs on the Shop Floor?

This PVC pipe-making machine is designed to maintain the same wall thickness and round shape throughout the length of the pipe. Due to a six-heating-zone system, this would allow better control over the melting of PVC, which helps evade the occurrence of possible defects such as uneven flow, surface marks, or brittleness.

The vacuum calibration and water spray cooling system keeps the pipe size stable even when running at higher speeds. This is especially useful when producing long batches where consistency matters more than short-term speed.

Key Features That Matter in Daily Use

Automatic Operation Without Complexity

The PLC-based system controls temperature, material feeding, haul-off, and cutting. Operators do not need advanced technical knowledge. Once settings are fixed, the machine runs smoothly with minimal supervision.

Strong and Durable Build

The use of stainless steel and high-grade alloys ensures resistance to corrosion and wear. This is important in Indian factories where machines often run multiple shifts.

Flexible Pipe Size Production

The machine supports standard conduit sizes like 16 mm, 20 mm, 25 mm, 32 mm, 40 mm, and 50 mm. Tooling can be changed easily, making it suitable for different market demands.

Energy Conscious Design

With a connected load of 75 KW, the machine balances output and power consumption, helping manufacturers control electricity costs.

HDPE Pipe Making Machine – Technical Specifications

| Specification | Details |

|---|---|

| Capacity | 500 kg/hr |

| Automation Grade | Automatic |

| Power Consumption | 150 KW |

| Machine Type | Fully Automatic |

| Brand | Plastivo Extrusion |

| Heating Zones | 8 Zones |

| Cooling System | Vacuum Tank and Water Spray Cooling |

| Control System | PLC-Based Automation |

| Material of Construction | Stainless Steel and High-Quality Alloys |

| Country of Origin | Made in India |

Where PVC Conduit Pipes Are Used?

- Residential and commercial electrical wiring

- Office buildings and shopping complexes

- Plumbing and drainage routing

- Cable protection for telecom and IT networks

- Industrial wiring installations

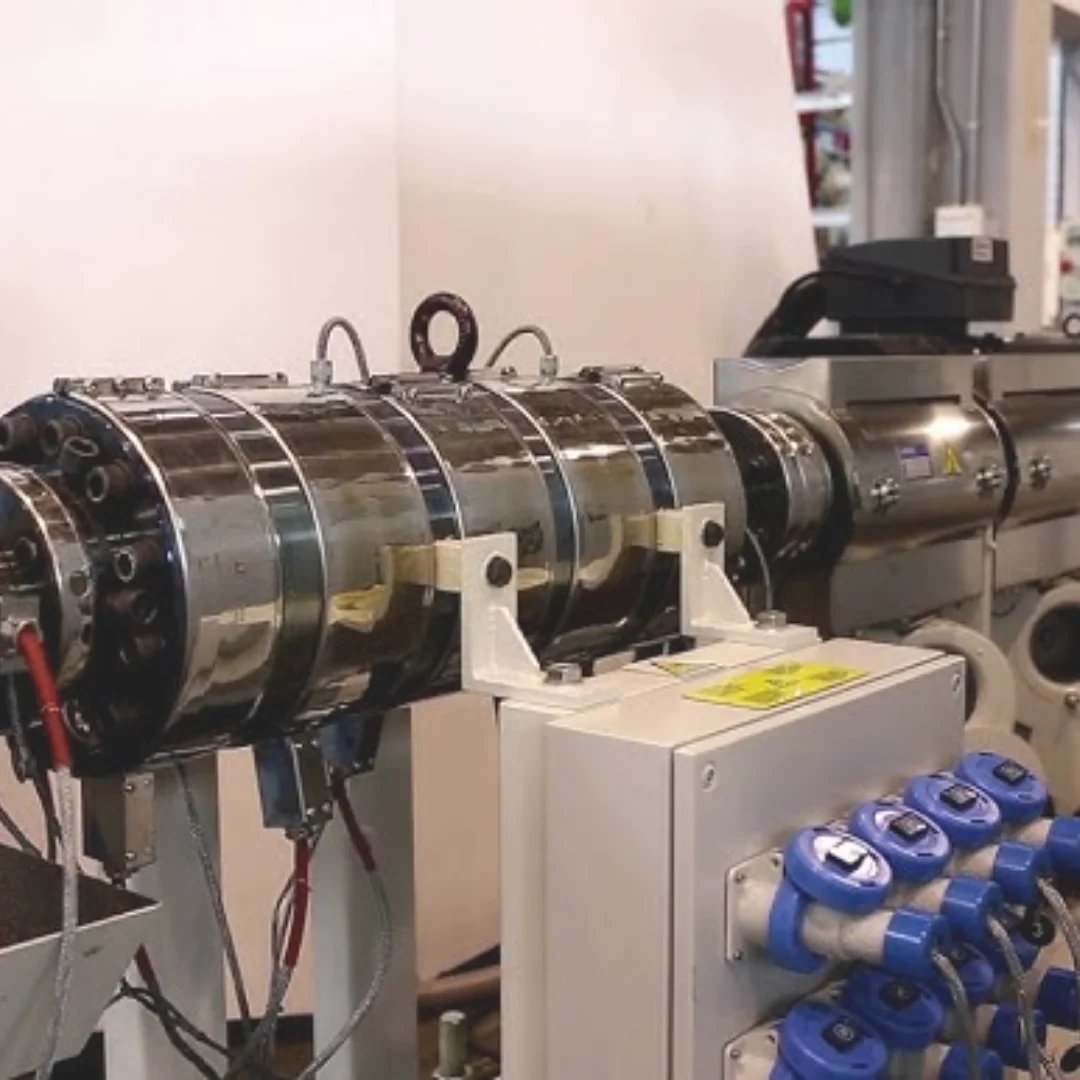

HDPE Pipe Making Machine for Heavy-Duty Applications

For manufacturing companies that focus on infrastructure and agriculture, the HDPE Pipe Making Machine is a basic tool to possess. The HDPE pipes will need to resist pressurized, chemical, and environmental effects for a long time. Any inconsistency during production can lead to rejection or failure in the field.

Plastivo’s HDPE Pipe Making Machine is built for continuous, high-speed production with stable melt flow and accurate sizing. With an output of up to 500 kg per hour, it suits medium to large manufacturing units supplying to government projects, irrigation schemes, and industrial buyers.

Designed for Consistent HDPE Pipe Quality

This HDPE Pipe Making Machine is suitable for HDPE, MDPE, PE80, and PE100 grades. The eight heating zones give precise temperature control, which is important when running higher output or larger pipe diameters.

The vacuum calibration tank and multi-stage cooling ensure that the pipe retains its roundness and wall thickness even at high speed. This reduces rejection and improves overall production efficiency.

Main Components Included in the HDPE Pipe Line

- High-output single screw extruder with hardened and nitrided screw

- Precision die head for smooth and uniform flow

- Stainless steel vacuum calibration tank

- Cooling tanks with a water spray system

- Caterpillar-type haul-off unit for stable pulling

- Servo-controlled pipe cutting unit

- Pipe stacker or tilting table

- PLC control panel with real-time monitoring

Practical Features of the HDPE Pipe Making Machine

High Production Capacity

Capable of producing up to 500 kg per hour, suitable for bulk orders and large projects.

Fully Automatic Control

PLC automation manages temperature, speed, and cutting cycles, reducing operator dependency and human error.

Wide Diameter Range

Standard pipe sizes from 20 mm up to 315 mm are supported, with custom options available up to 450 mm.

Strong Cooling System

Vacuum and water spray cooling ensure faster stabilisation and accurate sizing.

Optimised Power Usage

Despite high output, the 150 KW system is designed to keep energy usage within practical limits.

Applications of HDPE Pipes

HDPE pipes produced on this machine are widely used for:

- Drinking water supply lines

- Gas distribution networks

- Agricultural irrigation systems

- Sewage and drainage pipelines

- Cable ducting and protection

- Industrial fluid transport

Why Indian Manufacturers Choose Plastivo Extrusions?

Plastivo Extrusions focuses on machines that work reliably in real factory conditions. Both the PVC Pipe Making Machine and HDPE Pipe Making Machine are designed for long shifts, variable raw materials, and consistent output.

Manufacturers benefit from:

- Stable production with fewer breakdowns

- Simple operation and easy maintenance

- Energy-efficient performance

- Long machine life

- Strong technical support and training

Get in Touch for Details and Pricing

If you are planning to set up or upgrade your pipe manufacturing unit, Plastivo Extrusions offers complete guidance, from machine selection to installation and operator training. A reliable PVC Pipe Making Machine or HDPE Pipe Making Machine can significantly improve productivity and product quality when chosen correctly.

Get in touch with us today to discuss your pipe manufacturing requirements, machine specifications, and customised solutions that fit your production goals.

Discover More of Our Machinery

- Plastic Recycling Machine: Turns plastic scrap into usable granules quickly, ready for new production.

- Mother-Baby Recycling System: Streamlines plastic recycling with primary and secondary units working together.

- Plastic Recycling Granulator: Efficiently converts different types of plastic waste into reusable material.

- Twin Screw Barrel Manufacturer: Designed for high-efficiency PVC processing and material recovery.

Common Questions from Buyers

Yes, it is ideal for small to medium units looking for stable output.

Yes, it is designed for 24/7 operation.

Yes, installation and training support are included.

Yes, pipe size range, tooling, and layout can be customised.

HDPE, MDPE, PE63, PE80, PE100.